About us

After several years of research in 3D printing, the company has been manufactured stylish parts for your interior and exterior fittings.

All our products are made using a next generation 3D concrete printer, which builds parts by laying layers of concrete on top of one another, with the possibility to create complex shapes.

We are eco friendly.

3D technology allows us to minimize waste and optimize the tickness of our products to use less material and energy. We use durable materials, such as sand, cement and water. We work with the nearest suppliers as possible. for reduce the carrier impact.

The advantages of concrete

Longevity and durability.

Resistant to extreme climates.

UV resistant.

Strong.

100% recyclable.

High wind resistance, thanks to the density of the concrete.

Fire resistant.

and those of 3D printing

No need for mold or formwork.

Original shapes.

New shapes possible.

Material saving compared to poured concrete.

From one part to several tens.

Eco friendly, it takes only 4 liters of water to clean the printer.

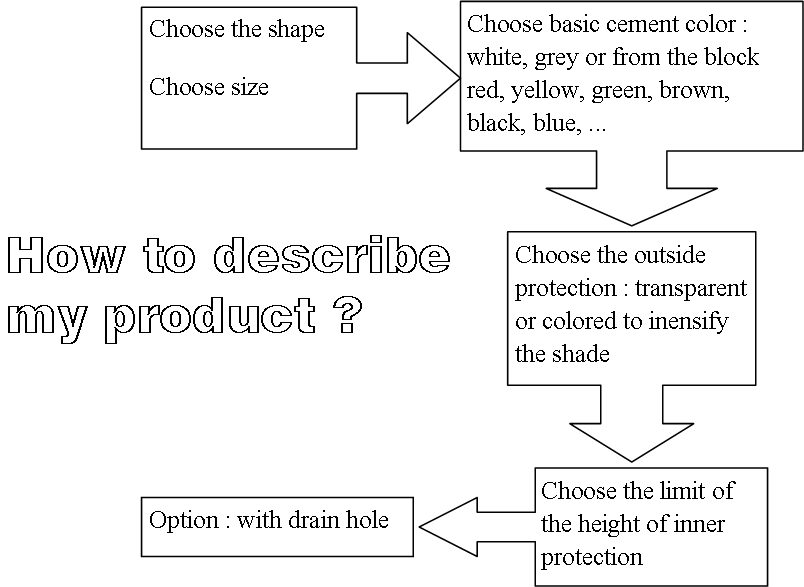

Simple drawing of 3d-line vase

1. Basic color of cement

2. Transparent or colored protection

3. Black waterproof interior protection.

h= limit of the height of black lacquer.

Usually h = 20 cm. Other heights on request.

4. Option : with drain hole.

The parts are delivered without hole.

Our vases, flower pots, planters and benches are maintenance free and perfect for outdoor use.

Our products are made in France in our workshops.

Research, development and our suppliers are based in France